Why Finger-Jointed and Edge-Glued Wood Products Are a Smart Choice for Trim and Paneling

Posted 4/14/2025 by Marketing

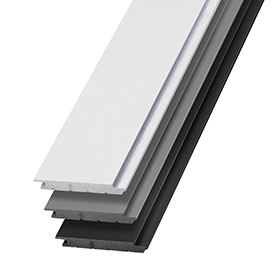

When it comes to choosing wood trim and wall paneling for your next project, performance and appearance are often weighed alongside cost. That's where engineered wood products like finger-jointed and edge-glued trim come in—offering the best of all worlds: high quality, clean aesthetics, and excellent value.

At Edge, our EvoTrim™, Premium Primed trim, and Timeless wall and ceiling boards are all engineered with these principles in mind. Here’s what makes finger-jointed and edge-glued products such a smart solution for both pros and homeowners—and when solid wood might be a better fit.

What Is Finger-Jointed and Edge-Glued Wood?

Finger-jointed wood is made by joining shorter pieces of kiln-dried lumber using interlocking "fingers" and a strong adhesive, creating long, straight, and dimensionally stable boards. This process not only reduces waste but also enhances consistency across every piece.

Edge-glued wood involves bonding boards side by side to form a wider, solid panel. This method creates a smooth, continuous surface that resists warping and cupping.

These manufacturing techniques are engineered for quality and consistency—perfect for trim and paneling applications where appearance and long-term performance matter.

The Benefits of Engineered Trim and Boards

-

Superior Stability

Because finger-jointed and edge-glued products are made from kiln-dried, defect-free wood, they resist common issues like warping, splitting, and twisting—especially important in exterior trim applications and high-humidity areas.

-

Smoother Surface for Finishing

Each board is machine-profiled and primed, making it ready for paint and ensuring a smooth, uniform finish. For example, our EvoTrim™ features a two-coat alkyd primer system for exceptional adhesion and long-term durability.

-

Sustainable and Cost-Effective

By utilizing smaller pieces of wood, engineered products maximize resource efficiency and reduce material waste. This allows for a more environmentally responsible—and often more budget-friendly—option compared to solid wood.

-

Consistent Appearance

Engineered boards are free from knots and other natural inconsistencies, making them a favorite among builders and painters who want a polished, professional look every.

When Solid Wood Might Be the Right Choice

While engineered wood offers many advantages, there are scenarios where solid wood trim or paneling may be preferable:

-

Visible Grain and Natural Character: For applications where the warmth and variation of natural wood grain is the focal point—like in rustic or craftsman-style homes—solid wood can offer an unmatched organic appeal.

-

Staining Instead of Painting: Solid wood is generally better suited to stain-grade applications, where the goal is to enhance rather than cover the natural beauty of the wood.

At Edge, we offer solid wood options alongside engineered products so you can choose what’s best for your project’s design vision and performance needs.

Choosing Finger-Jointed and Edge-Glued Wood

Finger-jointed and edge-glued wood trim products strike the perfect balance between performance, cost, and visual appeal. Whether you're trimming out a home’s exterior, finishing a ceiling, or paneling an interior wall, Edge’s EvoTrim™, Premium Primed trim, and Timeless® boards provide a reliable, ready-to-install solution that looks great and lasts.

Explore EvoTrim and order a sample today.

.png?h=680&iar=0&w=680&sc_lang=en&hash=79655ADC9BABEB4D30FBF4E39EED2EB3)

.jpg?h=1642&iar=0&w=2500&sc_lang=en&hash=901076773141504B0ED783F50744C086)