.jpg?sc_lang=en)

.jpg?sc_lang=en)

True™ (engineered)

- Cedar naturally resists decay and termites

- Finger-jointed and edge-glued for superior stability

- Small, tight knot appearance

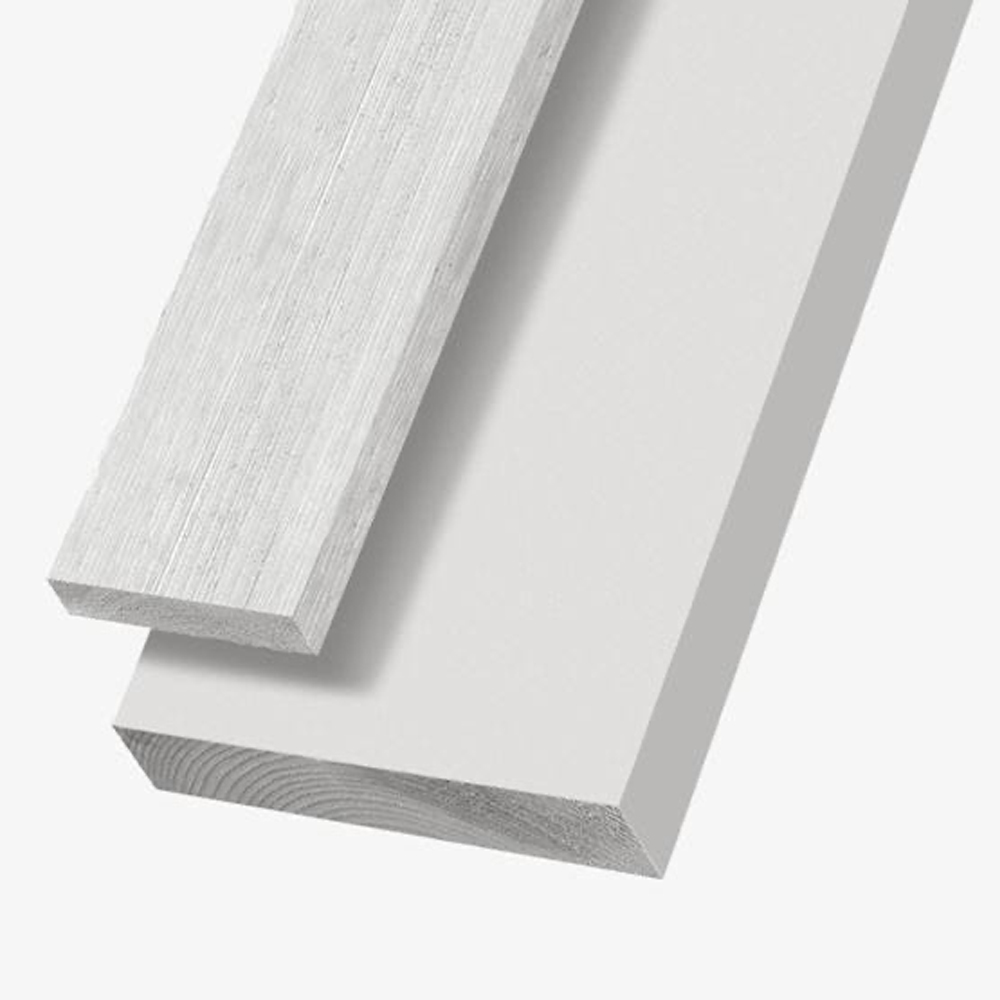

True™ finger-jointed trim is the premier exterior wood trim product on the market. Each of these cedar trim boards is finger-jointed and edge-glued with a high quality exterior adhesive that binds the wood during production. This process enhances the board’s performance, especially when a long run is desired. With True finger-jointed boards, there’s no need to worry about warping, cupping or twisting.

Boards are available with small tight knots, which offers the ultimate appearance. True’s first primer coat is an absorbing tannin blocker, while the second coat is fortified using a durable, non-blocking acrylic primer that prepares the surface on all sides for a superior finish.

Surface Textures

Two-sided board surface: S4S or S1S2E (resawn or combed).

Cedar Benefits

Naturally resistant to rot and insects.

Ready to Paint

Expertly primed board on all six sides for long-term performance.

Curb Appeal

The perfect finishing touch to elevate curb appeal on exterior projects.

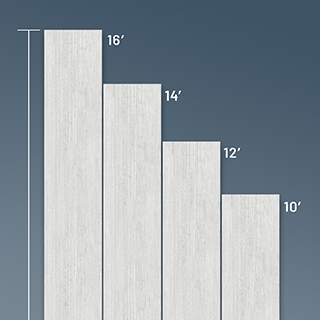

Various Sizes

1x3 through 1x6 and 2x4 through 2x12 in 16 ft. and 20 ft. lengths.

Straight and Stable

Finger-jointed and edge-glued for superior stability.

Protective Coating

Factory-applied coating enhanced with mildewcide for ultimate protection.

Ultimate Appearance

Cedar boards come available with small tight knots, offering a natural look.

-

Is Edge True treated?No, cedar naturally resists termites and rot, plus Edge True is protected by a high-performance PPG 2-coat latex system. The first coat protects against tannin bleed and the second provides a durable primer coat ready for paint.

-

Is Edge True an engineered product?Yes, both edge laminated and finger-jointed for stability and the best usable lengths.

-

Do you need to seal end cuts in the field while installing?Yes. Prime all cut ends and any areas were the primer has been damaged with PPG’s Seal Grip primer or an equivalent high-quality tannin blocking primer. Product must be finish coated on all 6 sides within 90 days of purchase with a high-quality exterior latex topcoat.

-

Is Edge True Reversible?Yes, we grade to the resawn face, but also have sanded the smooth side for the most versatile board in the industry.

-

What fastener types are recommended?

Stainless steel nails are the best choice, especially if the trim is to be finished with transparent, semitransparent stain, or bleaching oil. Use No. 304 stainless fasteners for general applications and No. 316 for seacoast exposures.

Hot-dipped galvanized as per ASTM A-153, aluminum and stainless steel fasteners are all corrosion-resistant and all can be used to fasten Cedar. Other types of fasteners (including electroplated and mechanically galvanized) are not recommended. They can rust and disintegrate and react adversely with the natural preservative present in cedar, resulting in stains and streaks.

For best result, use “splitless” ring shank siding nails. These nails have thin shanks and blunt points to reduce splitting. Textured heads should be used to reduce the glossy appearance of the nail head.

-

What is the preferred fastening method?

Hand nailing is preferred. Nails should be driven with care into the framing members. To ensure nailing accuracy, run chalk lines to mark framing locations. At mitered corners, near edges and near ends, nail holes may need to be pre-drilled to avoid splitting. Avoid the use of pneumatic nailers if possible. If a pneumatic nailer must be used, reduce the air pressure and tap nails flush.

Overdriven nails must be remedied immediately. Fill nail holes with exterior grade wood putty specifically designed for filling exterior nail holes.

How to choose the right

exterior trim

Primed trim and fascia products are some of the best on the market. See what trim option best suites your next project.

.png?h=680&iar=0&w=680&sc_lang=en&hash=79655ADC9BABEB4D30FBF4E39EED2EB3)